What is TG Guard?

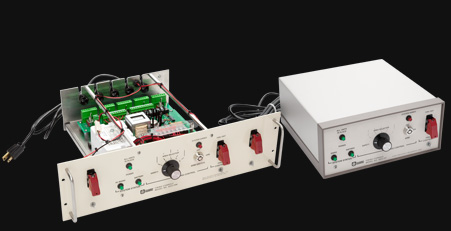

The TG Guard Security Protection System allows for the rapid deployment of powerful tear gas deterrent agent from a secure remote console.

The system is designed to move disruptive inmates out of an affected area without sending in correctional officers who may be harmed or taken hostage. Through the strategic arrangement of dispensers installed in ceilings or elevated fixtures the system moves the inmates in a controlled fashion. Dispenser placement and the amount of irritant agent discharged determines in which direction and in what manner the inmates move.

With the TG Guard Security Protection System the ability of staff to isolate, contain, and manage the potential escalation is greatly increased. As a result, the incidents of serious injury to both staff and inmate population are greatly diminished. In institutions equipped with the TG Guard Security Protection System, the correctional staff has the security of knowing they walk into a riotous situation with a tremendous advantage, one that levels the playing field and makes the use of deadly force far less likely.

Features

Remote-fired, stationary chemical agent network

stops trouble fast, while protecting inmates,

personnel and property.

Can be easily retrofitted to existing

facilities, or designed into new

construction.

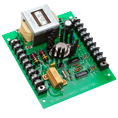

Over 15 years of proven technology that

will not become obsolete. Spare parts

readily available.

In use today in correctional facilities,

embassies, and other sensitive installations

around the world.

Entire system can be operated by one individual.